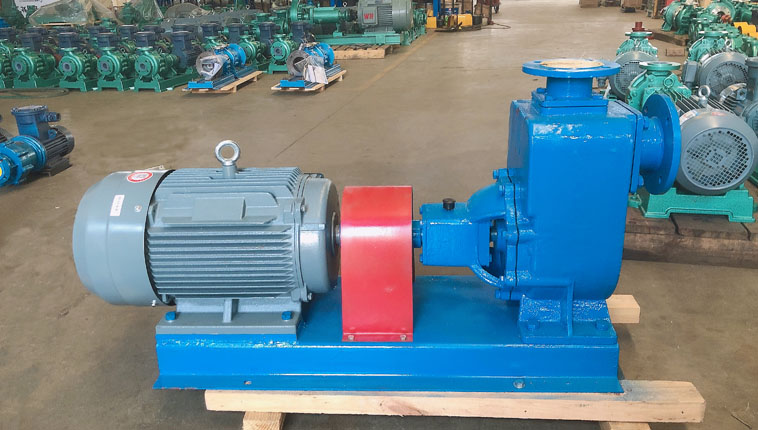

ZX stainless steel self-priming pump has the advantages of compact structure, convenient operation, smooth operation, easy maintenance, high efficiency, long life and strong self-priming capacity. The pipeline does not need to install the bottom valve, and only needs to ensure that the quantitative liquid intake is stored in the pump body before working.

Widely used: suitable for urban environmental protection, construction, fire fighting, chemical industry, pharmaceutical, electric power, electroplating, papermaking, petroleum, equipment cooling and so on.

ZX stainless steel self-priming pump (preparation before start).

1. Check whether the storage fluid in the pump is higher than the upper edge of the impeller. If it is insufficient, the liquid can be injected directly into the pump body from the filling port on the pump shell, and the pump should not start operation under the condition of insufficient liquid storage, otherwise the pump can not work normally and the mechanical seal can be easily damaged.

2. Check whether the moving parts of the pump are stuck and bumped.

3. Check whether the nut at the bottom of the pump body and each joint is loose or not.

4. Check the coaxiality and parallelism of the pump shaft and the motor spindle.

5. Check whether the inlet pipeline is leaking or not. If there is air leakage, you must try to discharge it.

6. Open the valve of the suction pipe and slightly open (do not fully open) the outlet control valve.

Start and operate

1. Click on the self-priming pump and pay attention to whether the steering of the pump shaft is correct.

2. Pay attention to whether there is abnormal sound and vibration when turning.

3. Pay attention to the readings of pressure gauges and vacuum gauges. After starting, when the readings of pressure gauges and vacuum gauges fluctuate for a period of time and indicate stability, it indicates that the pump has been filled with liquid and goes into normal infusion.

4. Before the pump enters the normal infusion operation and during the self-priming process, special attention should be paid to the rise of the water temperature in the pump. If the process is long and the water temperature in the pump is too high, then stop the pump to check the reason.

5. If the liquid temperature in the pump is too high and cause self-suction difficulty, then you can temporarily stop the machine and use the liquid in the spit line to return to the pump or directly replenish the liquid to the pump at the filling and storage port on the pump body, so that the liquid temperature in the pump can be reduced, and then start.

6. If strong vibration and noise occur in the working process of the pump, it may be caused by cavitation of the pump. There are two causes of cavitation: one is that the velocity of the inlet pipe is too high, and the other is that the suction is too high. The outlet control valve can be adjusted when the flow rate is too high, and the reading of the temperature pressure meter should be discharged in time when the inlet pipeline is clogged, but it is suitable to reduce the installation height of the pump when the suction is too high.

7. Due to the solid stop of the pump during the working process, the outlet control valve should be slightly opened (not fully closed) when starting, which is beneficial to the discharge of gas from the outlet in the process of self-priming, and ensures that the pump starts under a lighter load.

8, pay attention to check whether there is leakage in the pipeline system.

Stop pump

1. The gate valve on the spit line must be closed first.

2. Stop the pump from turning.

3. In the severe cold season, the storage liquid in the pump body and the water in the cooling chamber of the bearing body should be emptied to prevent frost cracking.

+86 18130251359

+86 18130251359 teflowpumps@tlpumps.com

teflowpumps@tlpumps.com

+86+0563-5093318

+86+0563-5093318